Nested Spirawave® Wave Springs can be used in applications that normally require stacks of single-turn springs or when a single-turn cannot achieve the force required within the assembly. Below are a few examples of where and how a Nested Wave Spring can be used.

© 2019 SMALLEY STEEL RING COMPANY. ALL RIGHTS RESERVED.

Nested Wave Spring Applications

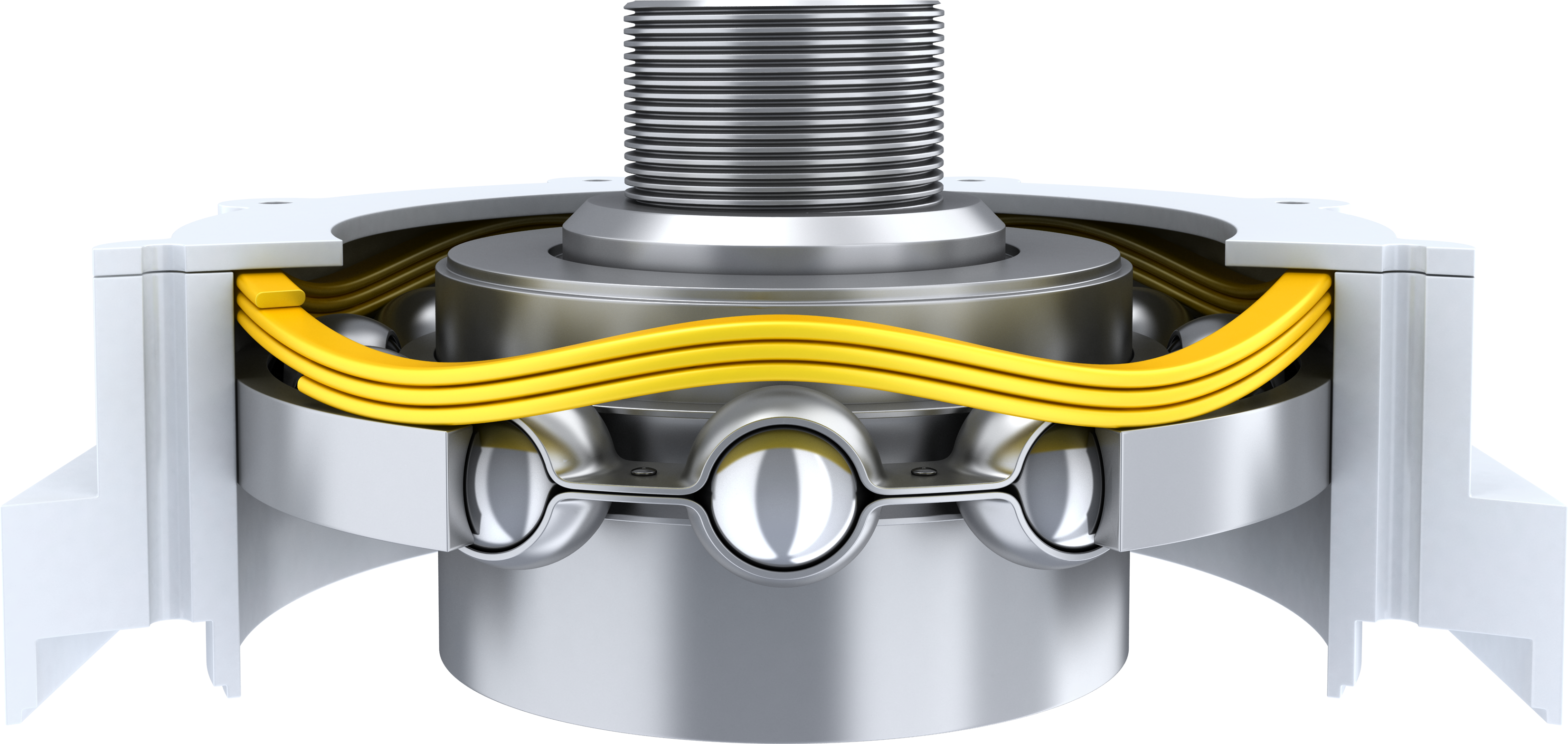

In very high load applications, a three-turn spring produces the high forces necessary for heavy duty bearing preload. Bearing preload is necessary in order to limit noise and vibration within an assembly.

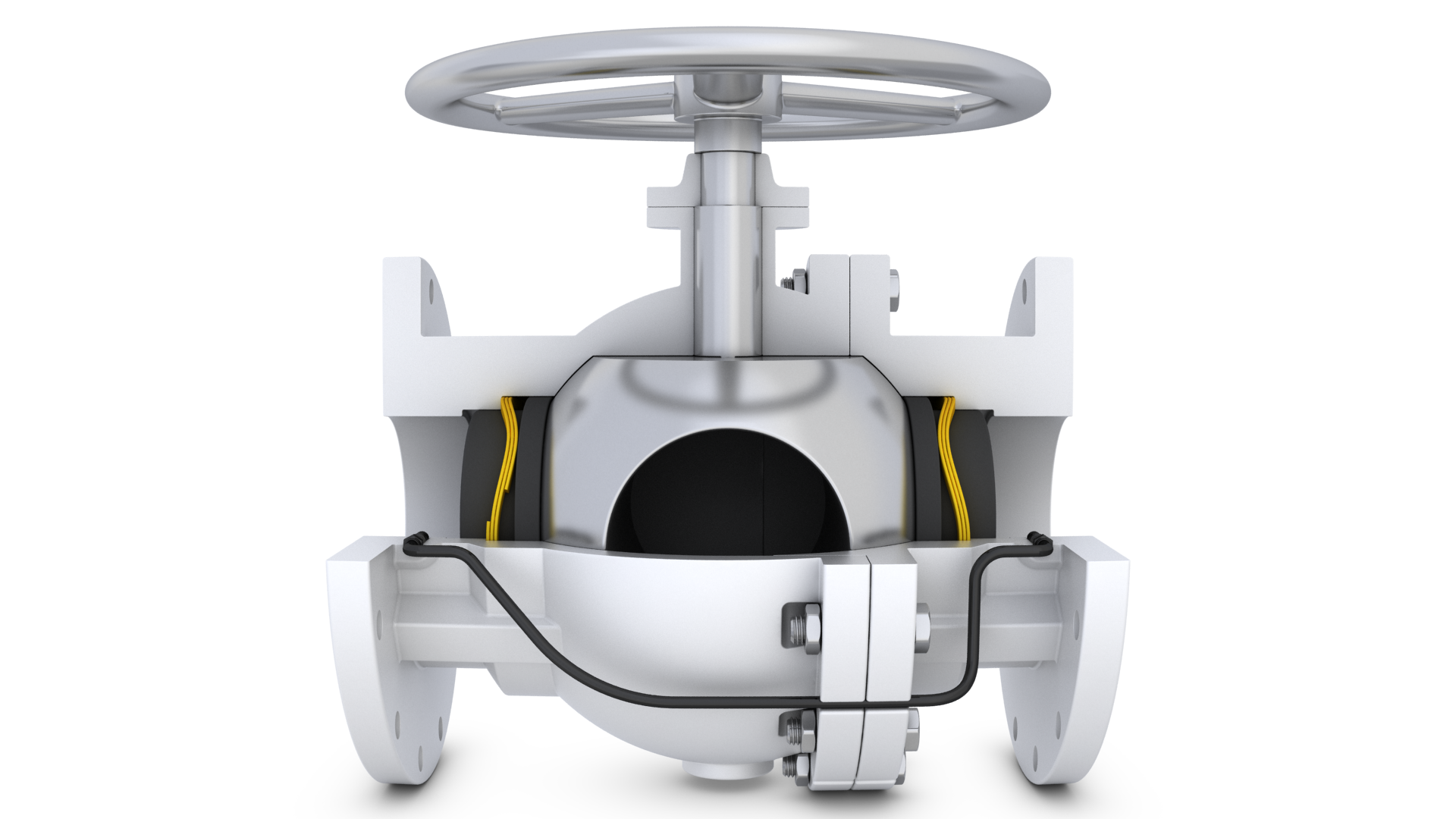

When pressure is applied to the sealing surface, the Nested Spirawave will compress to keep the seal closed. As the seal wears, the spring keeps pressing the seal tight against the sealing surface. Nested Spirawave Wave Springs can provide a very high spring force with a very low profile in a valve where space is limited.

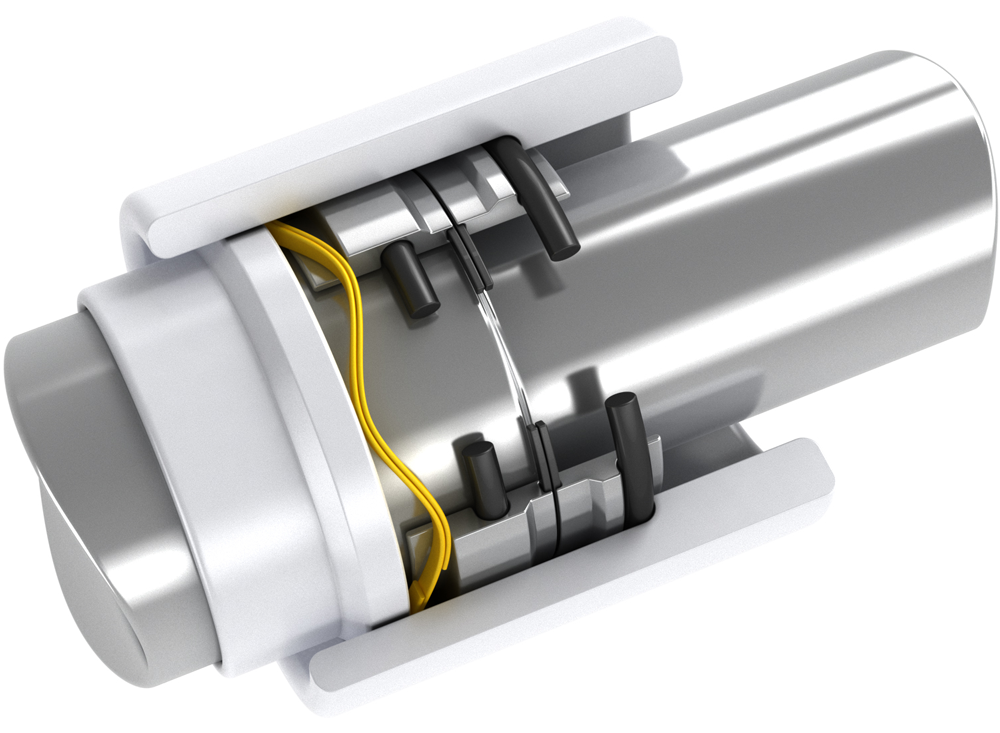

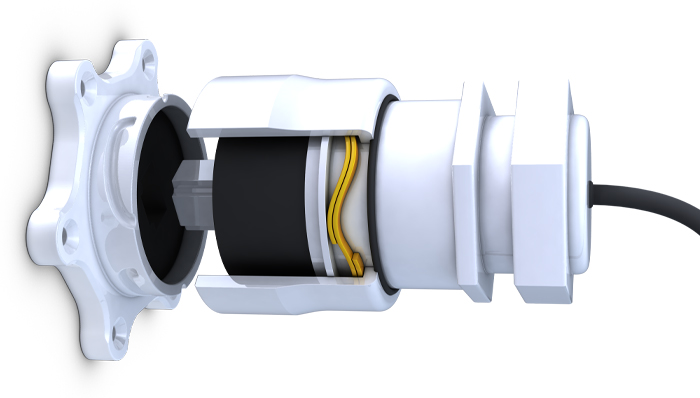

In a connector, the male end rotates following the groove contour in the female end, and the two-turn Nested Spirawave provides the preload between the two halves. This wave spring provides the high load necessary in a very tight radial and axial space.

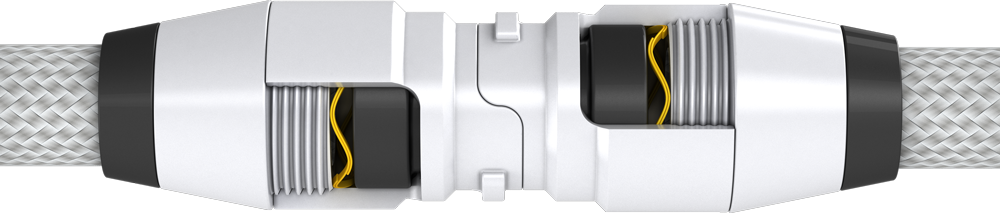

A two-turn Nested Spirawave replaces a single-turn wave spring stack to provide the required spring force to hold the ends together. A small amount of travel allows for necessary movement for the ends to disconnect when required.

Bearing Preload

Valve

Connector

Cable